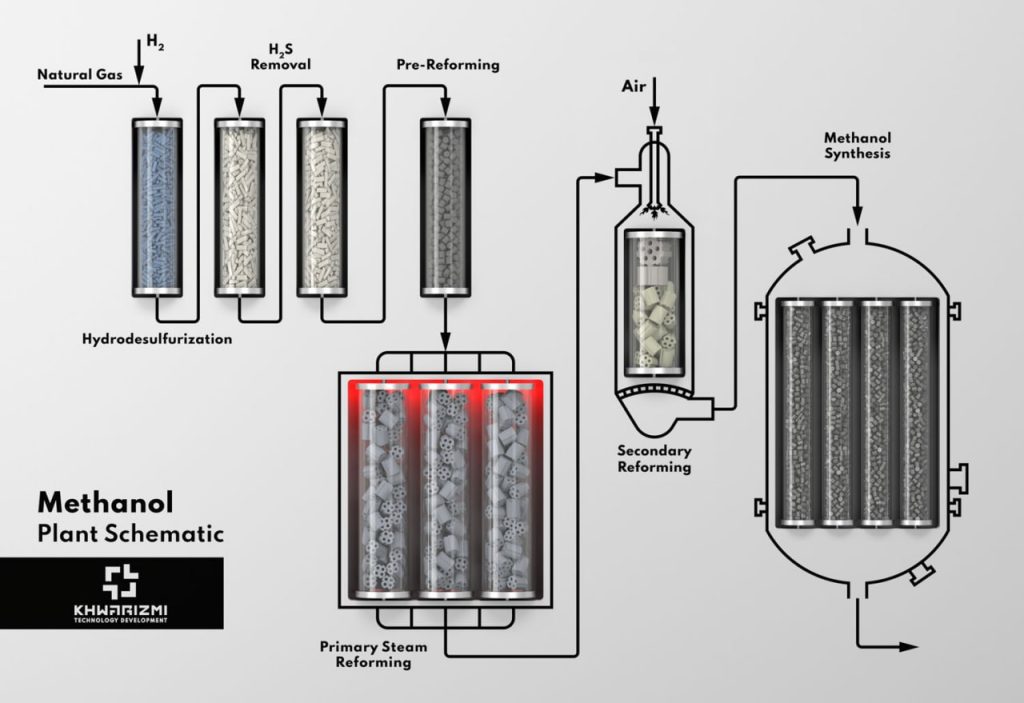

Methanol production is one of the most profitable means of adding value to natural gas. Methanol can be generated from a wide range of carbon and hydrogen sources. Currently, large-scale production is dominated by the conversion of fossil resources, mainly natural gas and coal, to carbon monoxide and hydrogen (synthesis gas or syngas) as the intermediate for catalytic methanol synthesis.

In methanol plants with natural gas as the source of fossil fuel, everything begins with the treatment of natural gas. Each natural gas reservoir contains different types and levels of poisonous and harmful ingredients, like hydrogen sulfide, organic sulfur containing materials, mercury, halogens and etc. which can permanently or temporarily reduce the activity of the downstream catalysts and obviously must be removed.

Accordingly, some guarding materials should be installed to protect those catalysts against poisons and extend their lifetime. The type and concentration of the harmful materials in the natural gas stream as well as some specific operating parameters determine the plant design configuration and types of purification catalysts.